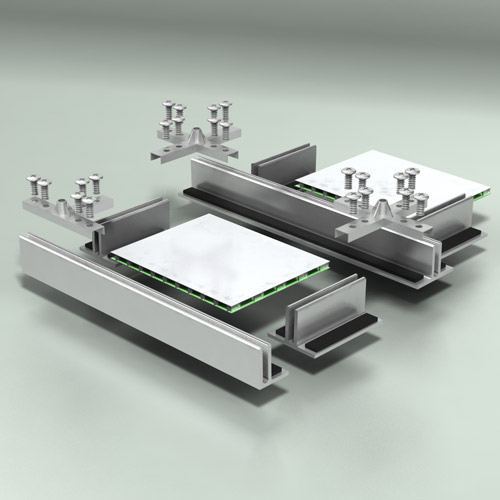

Cleanroom Aluminum Ceiling Panels

Available Nation Wide

Webb Core Cleanroom Ceiling Panels are constructed from an aluminum honeycomb core expanded into a hexagonal structure sandwiched by aluminum skin and bonded with our custom adhesive.

Our panels are specifically designed for ceiling cleanroom applications but are used for solutions in other industries. The standard skin is typically constructed from a 0.032 aluminum sheet with an acrylic finish.

We also offer diamond plate panels constructed from 0.40 aluminum with a bright finish on topside and standard skin on the opposite side.

Ceiling Panels

All ceiling panels are available in 2' x 2', 2' x 4', 4' x 4' and custom sizes

1/4" x 2'-0" x 4'-0"

- Thickness: 1/4"

- Core: ¾" cell .003"

- Deflection:

- Maximum Load:

- .25" x 2' x 4'- Blank-Off Ceiling Panel (Non-Walkable)

- .25" x 2' x 4'- Specification

1/2" x 2'-0" x 4'-0"

- Thickness: 1/2"

- Core: ½" cell .003"

- Deflection:

- Maximum Load:

- .50" x 2' x 4' - Walkable Ceiling Panel

- .50" x 2' x 4' - Specification

1" x 2'-0" x 4'-0"

- Thickness: 1"

- Core: ¾" cell 0.003"

- Deflection: 0.095 inches @ 437 lbs. Applied load

- Maximum Load: 1800 lbs. Per ASTM 72-95

- 1" x 2' x 4' - Walkable-Blank-Off

- 1" x 2' x 4' - Specification

2-3/4" x 2'-0" x 4'-0"

- Thickness: 2-3/4"

- Core: ¾" cell 0.003"

- Deflection: 0.0180 inches @ 400 lbs. Applied load

- Maximum Load: 5600 lbs. Per ASTM 72-95

- 2 ¾" x 2'-0" x 4'-0" Walkable Ceiling Panel

- 2 ¾" x 2'-0" x 4'-0" Specification

Physical Properties

- Trade Name: Spec-Stat

- Products Name: H/G White Conductive Epoxy

- Product Code: 657-1-W-1654

- Product Type: Epoxy/reverse roll coat

- Intended End Use: Interior Wall Panels

- Chemical Resistance: Available upon request

- 1" x 4' x 4' - Ceiling Panels Walkable Blank Off Load Testing

- 2 ¾" x 2'-0" x 4'-0" Walkable Ceiling Panels Blank Off-Load Testing

- 2 ¾" x 4' x 4' - Walkable Ceiling Panels Blank Off-Load Testing

Static Control

Static control can be built into the system by utilizing the low outgassing conductive paint coatings. Bright finish aluminum tread sheets, roll coated mill finish or anodized flat sheets may be utilized for the plenum surface.

- Laboratory: 60 Gloss 50+

- Production: 60 Gloss 50+

- Minimum Pencil Hardness: 2H Eagle Turquoise

- Solvent Resistance: 50+ Double Rubs, Mek

- Reverse Impact: 30 in. lbs. No tape lift off

- Resistivity: 10^6 - 10^8 Ohms

- Weight: Approx. 2.1 lbs./sq. ft.